Hindustan Nylons an ISO 9001:2015 Certified Company Manufactures Chemically Modified PTFE Products such as Moulded bushes, Moulded rods, Skived sheets, Expansion joints, Gaskets, Valves & Pump components in virgin as well as Filled Grades.

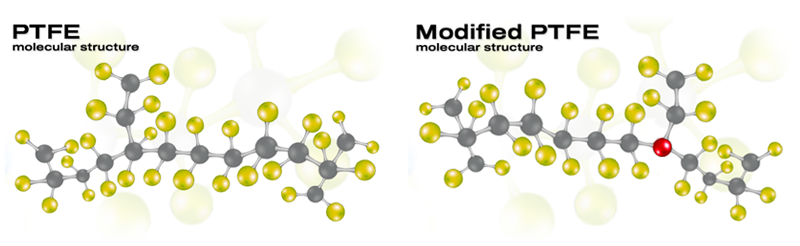

To over come some of the weaknesses of conventional PTFE , scientists has developed the new chemically modified PTFE and have improved some of the properties for the benefit of consumers. and is often considered a Second-Generation Polytetrafluoroethylene, is a refined version of the original material. It's a copolymer based on tetrafluoroethylene, with a small addition of PerfluoroPropylVinylEther (PPVE). This strategic modification, less than 1% in quantity, significantly enhances the performance of standard PTFE.

The modified chemical structure of the polymer enables us to differentiate between Standard and Modified PTFE. The latter's molecular weight, reduced to one-fifth that of Standard PTFE, facilitates superior particle fusion. This enhances weldability, significantly improves the joining process for components made of Modified PTFE.

The relatively low molecular weight of Modified PTFE would normally give rise to an end product with higher crystallinity and hence lower mechanical properties. However, the addition of PerfluoroPropylVinylEther (PPVE) modifier in Modified PTFE specifically inhibits crystallization, thus increasing the amorphous content while maintaining the desired mechanical properties of Standard PTFE. Furthermore, the modifier ensures better distribution of the crystallites in the amorphous matrix and dramatically reduces cold flow.

Chemically Modified PTFE parts offers new opportunities for designing & engineering high performance products to get following working advantages.

| Sr No. | Parameter | Standard | Conventional PTFE Value | Modified PTFE Value |

|---|---|---|---|---|

| 1 | Colour | Visual | Milky White | Translucent White |

| 2 | Density | ASTM-D-792 | 2.1~2.2 gm/cc | 2.1~2.15 gm/cc |

| 3 | Tensile Strength | ASTM-D-638 | 200~300 kg/cm2 | 300~400 kg/cm2 |

| 4 | Elongation | ASTM-D-638 | 250~350% | 350~450% |

| 5.a | Compressive Strength at 1% Deformation | ASTM-D-695 | 35~40 kg/cm2 | 45~60 kg/cm2 |

| 5.b | Compressive Strength at 10% Deformation | ASTM-D-695 | 140~145 kg/cm2 | 170~200 kg/cm2 |

| 6 | Coefficient Of Friction | - | - | - |

| A | Static | ASTM-D-1894 | 0.05 | 0.045 |

| B | Dynamic | 0.04 | 0.035 | |

| 7 | Hardness | ASTM-D-2240 | 50~55 Shore D | 50~60 Shore D |

| 8 | Service Tempreature | ASTM-D-648 | - 200~+260℃ | - 200~+260℃ |

| 9 | Water Absorption | ASTM-D-570 | 0% | 0% |

| 10 | Dielectric Strength | ASTM-D-194 | 10~15 Kv/mm | 30~32 Kv/mm |

| 11 | Service Conditions (Properties) | -- |

|

|

| 12 | Applications | -- | Gaskets, Bellows, Food/Contact and Medicine/Human Consumption Applications | Diaphragms, Components of Mechanical Seals, Vesel Lining. |

| Permeant | Specimen Thickness, mm (in) |

Vapor | Liquid | Gas | |||

|---|---|---|---|---|---|---|---|

| PTFE | M-PTFE | PTFE | M-PTFE | PTFE | M-PTFE | ||

| Perchloroethylene | 1 (0.04) | 5.5 | 2 | 13 | 4 | - | - |

| Perchloroethylene | 2 (0.08) | 1.4 | 0.1 | 0.019 | 0.005 | - | - |

| Perchloroethylene | 3 (0.16) | 0.08 | 0.05 | 0.006 | 0 | - | - |

| Perchloroethylene | 4 (0.20) | 0.055 | 0.050 | - | - | - | - |

| Hexane | 5 (0.08) | 3.4 | 0.2 | 23.4 | 0 | - | - |

| Hexane | 6 (0.20) | 0.045 | 0.015 | - | - | - | - |

| MEK | 7 (0.08) | ||||||

| MEK | 8 (0.20) | 36.3 | 23.3 | 49.4 | 34.2 | - | - |

| HCI, 20% | 9 (0.04) | 0.4 | 0.1 | - | - | - | - |

| Helium | 10 (0.08) | - | - | - | - | 93 | 1 |

| Helium | 11 (0.20) | - | - | - | - | 0.18 | 0.12 |

When seeking a dependable source for modified PTFE, prioritizing quality and reliability is crucial. Key considerations include-

Quality and Expertise: Is Critical Combination in PTFE Prducts manufacturingHindustan Nylons sources raw materials from reputable manufacturers. At Hindustan Nylons, we foster strong relationships with leading PTFE resin and chemical suppliers, granting us access to the market's full spectrum of polymer resins.

Experience is paramount. Hindustan Nylons proven track record in producing and supplying modified PTFE tailored to industry's specific needs. Hindustan Nylons, a seasoned player in the fluoropolymer field for over 35 years, boasts superior know-how and substantial production capacity to deliver all grades of PTFE materials."

In conclusion, modified PTFE's superior properties make it ideal for diverse applications. When selecting a supplier, prioritize quality, expertise, experience, capabilities, and certifications to ensure optimal product performance.

For further technical information or demand, please feel free to contact us at contact@h-n.co.in

Modified PTFE Components as per standard and specific sizes / drawing & in standard - Filled compositions can be available, subject to minimum order quantity.

Hindustan Nylons manufacturers Ram Extruded Rigid Pipes, Skived Sheets / Vessel Liners, Bellows / Expansion Joints, Valve Components, Mechanical Seal Components, Pump Components process in variety of standard sizes, in Virgin m-PTFE & Filled m-PTFE.

Modified PTFE excels in applications requiring seamless, pore-free surfaces. Its exceptionally smooth texture makes it ideal for handling and storing ultra-pure chemicals, as well as for wet-chemical processes. Additionally, its non-stick properties enable efficient cleaning and significantly reduce downtime.

| Typical Application | Physical properties |

|---|---|

| PTFE Gaskets, PTFE seals | Creep resistance |

| PTFE Ball valve seats | Creep resistance |

| Automotive parts Power steering seals A/T seals Air conditioner seals Others |

Creep resistance Flexural fatigue resistance Wear resistance |

| PTFE Bellows | Flexural fatigue resistance |

| Diaphragms | Flexural fatigue resistance |

| Metal inserts molded parts | Stress cracking resistance |

| Base powders (Compounds) | Creep resistance Flexural fatigue resistance |

Modified PTFE comes in various grades, each with distinct properties and applications. At Hindustan Nylons, we maintain direct relationships with leading PTFE resin and chemical suppliers, granting us full access to the market's diverse polymer resin offerings. This robust supply chain ensures reliable and consistent product availability, empowering us to support your projects with confidence.

There are various Virgin and Filled grades available in m-PTFE, subject to minimum order quantity.